SERVICE

UPC bases on supplying best quality products and the Environment- friendly packing solution, which meets modern trends,the material is to be lighter, stronger, and recyclable.

-

Production Line Audit

Professional skiller from UPC will come to Audit every production line before running the mass production for each products,Read More -

Factory Audit Details

We have a complete set of product review process to ensure the quality of each product.Read More -

Quality Control

Products must be manufactured in accordance with drawings and technical documents that have been approved by the prescribed procedures and meet the standard.Read More -

Design

Professional glass bottle designers, designed for each product, to create a practical and aesthetic products.Read More

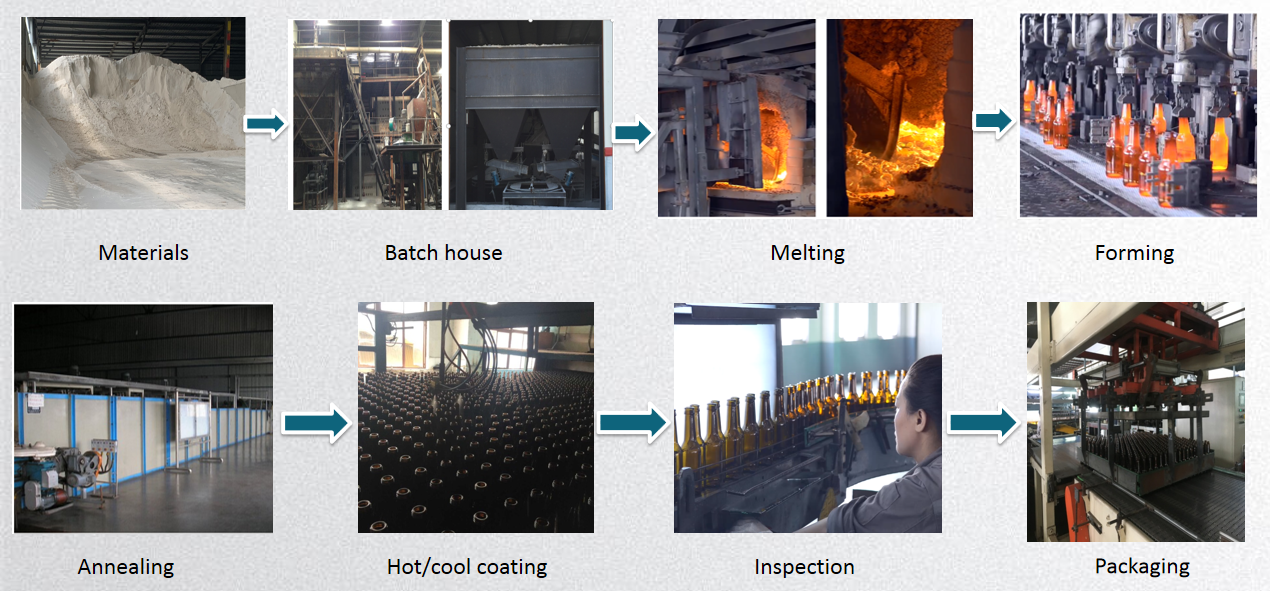

Production Line Audit

Professional skiller from UPC will come to Audit every production line before running the mass production for each products, make sure it is to meet the standard for packaging, below is the process of production by Audit:

1. Raw materials

Silica sand, Soda

ash, limestone, and cullet (crushed glass),

others

2. Batch House

Weighing

and mixing of raw materials, and transport to

the hopper at the melting furnace

3.

Melting

Melting of mixed raw

materials about 1,550 c° in the melting

furnace

4. Feeding

Feeding

of glass gob at optimum temperature suitable

to bottle weight and shape is fed into a glass

bottle-forming machine via the feeder

5.

Forming

Forming of bottle by the

glass bottle-forming machine for designed

bottle shape

6. Annealing

Annealing

of bottles as they leave the glass

bottle-forming machine

8.Coating

After Annealing, cool end coating make bottle more stonger

7. Inspection

A bottle is

strictly checked on Automatic inspection

machine and visually inspect each bottle to

confirm quality by skilled technicans

8. Packing

Using the safe pallet / carton packing

Factory Audit Details

- Beer Bottle

- Pharmaceutical Bottle

- Cosmetic Bottles

- Food Jars & Bottles

- Cap

|

Factory Audit Details |

|

|

Product color: |

Amber& Green& Flint soda lime glass bottle |

|

Furnace area and Yield |

Flind soda lime color Furnace

covers an area of

66.6㎡; |

|

Covers an area: |

The plant covers an area of 113,390㎡ |

|

production line: |

IS Machines : Emhart |

|

Production Capacity: |

the daily output of bottle about Nine hundred thousand/day(based on the glass bottles with capacity of 500ml) |

|

Environmental treatment |

Take “Sulphur” and “smoke of gunpowder” off from end gas |

|

Spray way: |

hot/cold coating |

|

Detection : |

1: For beer glass bottle: inspected by manpower and automatic inspection machine. 2: Inspection process:

[2] Package staff inspect the loading carton , [3] QC inspection visual , [4] sampling inspection before storing . [5] shock resistance machine (CYETGY-2), [6] conductivity meter DDS-11A, [7] Weighing scale FA2004, [8] griddle 5 pcs, [9] anti-seismic (hot/cool water tank) internal pressure machine GPT-1, [10] water resistance equipment YXQ-280SD |

|

Packing: |

Automatic packing machine |

|

Pallets / cartons with shrink wrapped: |

It can be packed by wooden pallet according to customer's requirement . |

|

Factory Audit Details |

|

|

Product color: |

Amber,Clear,Green,Blue |

|

Furnace area and Yield |

Furnace covers an area of 73㎡, glass material 100ton/day |

|

Covers an area: |

The plant covers an area of 12,0000㎡,warehouse cover an area of 12000㎡ |

|

production line: |

Three Furnace,six production

line,IS Machines : Jiafeng |

|

Production Capacity: |

Two million |

|

Environmental treatment |

Take “Sulphur” and “smoke of gunpowder” off from end gas |

|

Spray way: |

hot/cold coating |

|

Detection : |

1.For pharmaceutical bottle,there is four inspection line, the inspection machine is from beijing dahen image company.Inspected by manpower and automatic inspection machine.

2: Inspection process: |

|

Packing: |

Automatic packing machine and manpower |

|

Pallets / cartons with shrink wrapped: |

It can be packed by wooden pallet or carton box according to customer's requirement |

|

Factory Audit Details |

|

|

Name of Factory: |

XIAMEN UPC IMP.&EXP. CO.,LTD |

|

Product color: |

soda lime clear glass bottle; Other colors can be customized |

|

Furnace area and Yield |

Furnace covers an area of 30㎡, glass material 60ton/day |

|

Covers an area: |

The plant covers an area of 78000㎡ |

|

production line: |

IS Machines :Shandong Sanjin Glass

Machinery , , one furnace, |

|

Production Capacity: |

the output of bottle about one million /day |

|

Environmental treatment |

Take “Sulphur” and “smoke of gunpowder” off from end gas |

|

Spray way: |

hot/cold coating |

|

Detection : |

1: inspected by manpower and automatic inspection machine. 2: Inspection process: [1] Production Staff inspection initially , [2] Package staff inspect the loading carton , [3] QC inspection visual , [4] sampling inspection before storing . Inspece M,modle JYH300 is a servo driven rotary inspection machine,which allowing handling up to 200 containers per minute. |

|

Packing: |

Automatic packing machine and manpower |

|

Pallets / cartons with shrink wrapped: |

It can be packed by wooden pallet or carton box according to customer's requirement |

|

Factory Audit Details |

|

|

Product color: |

Soda lime clear glass bottle; Other colors can be customized |

|

Furnace area and Yield |

Furnace covers an area of 30㎡, glass material 60ton/day |

|

Covers an area: |

The plant covers an area of 59940㎡ |

|

production line: |

IS Machines : Jiafeng , type:

HQD6D-108DSD , one

furnace, |

|

Production Capacity: |

the output of bottle about one hundred thousand/day |

|

Environmental treatment: |

Take “Sulphur” and “smoke of gunpowder” off from end gas |

|

Spray way: |

hot coating |

|

Detection : |

1: Inspected by automatic inspection machine. 2: Inspection process: [1] Production Staff inspection initially , [2] Package staff inspect the loading carton , [3] QC inspection visual , [4] sampling inspection before storing . [5] shock resistance machine (CYETGY-2), [6] conductivity meter DDS-11A, [7] Weighing scale FA2004, [8] griddle 5 pcs, [9] anti-seismic (hot/cool water tank) internal pressure machine GPT-1, [10] water resistance equipment YXQ-280SD |

|

Packing: |

Automatic packing machine and manpower |

|

Pallets / cartons with shrink wrapped: |

It can be packed by wooden pallet or carton box according to customer's requirement . |

| Factory Audit Details | |||||||

| Name of Factory: | XIAMEN UPC IMP.&EXP. CO.,LTD | ||||||

| Product color: | colors can be customized. We are specilized in the main plastic blow molding, injection molding, plastic food containers, etc. | ||||||

| Yield | Pre investment 2 million with strong strength of independent plant, was established in 2001, has been certified by QS/ | ||||||

| Covers an area: | It is located in Huli District, Xiamen city Fujian | ||||||

| production line: |

Companies adhering to the

"customer first, forge

ahead" business philosophy, adhere

to the "customer first"

principle to provide our clients

with quality services.

|

||||||

| Detection : |

1: inspected by manpower and automatic inspection machine. 2: Inspection process: [1] Production Staff inspection initially , [2] Package staff inspect the loading carton , [3] QC inspection visual , [4] sampling inspection before storing . Inspece M,modle JYH300 is a servo driven rotary inspection machine,which allowing handling up to 200 containers per minute. |

||||||

| Packing: | manpower | ||||||

| Pallets / cartons with shrink wrapped: | It can be packed by wooden pallet or carton box according to customer's requirement . | ||||||

Quality Control

4.1 Products must be manufactured in accordance with drawings and technical documents that have been approved by the prescribed procedures and meet the standard.

|

Capacity(Nominal Value or

Full-container)L,

ml

|

Tolerance

ml

|

|

25<L≦50

|

±3

|

|

50<L≦100

|

±4

|

|

100<L≦200

|

±8

|

|

200<L≦300

|

±10

|

|

300<L≦500

|

±12

|

|

500<L≦750

|

±15

|

|

L>750

|

±25

|

|

Note: Tolerances for special

products can be determined in

accordance with clients’

requirements.

|

|

|

Bottle Mouth OD D,mm

|

Tolerance,mm

|

|

20<D≦60

|

±0.35

|

|

60<D≦80

|

±0.45

|

|

80<D≦100

|

±0.6

|

|

Note: Tolerances for special

products can be determined in

accordance with clients’

requirements.

|

|

|

Item Name

|

Index

|

|||

|

Mouth Flatness,mm

|

Mouth OD

mm

|

≦60

|

≦0.4

|

|

|

≦90

|

≦0.6

|

|||

|

>90

|

≦0.8

|

|||

|

|

|

≦60

|

≦0.6

|

|

|

≦90

|

≦0.8

|

|||

|

>90

|

≦1

|

|||

|

Body Joviality,mm

|

≦(0.5+0.01)×2

In the formula:D——body

diameter,mm

|

|||

|

Mouth Defects

|

Mouth Spikes

|

Not allowed

|

||

|

Defects on the sealing surface

that affect the sealing

performance

|

Not allowed

|

|||

|

Mouth screw defects

|

Not allowed

|

|||

|

Apparent defects on mouth convex

ring

|

Not allowed

|

|||

|

The mouth concaves in and is

without an inner stopper

|

Allowed

|

|||

|

The mouth concaves in in a degree

that affects the sealing

performance

|

Not allowed

|

|||

|

Stoned

|

Diameter more than 1.5mm

|

Not allowed

|

||

|

Diameter between 0.3mm~1.5mm, no

cracks around, not more than

|

2

|

|||

|

Diameter below 0.3mm, visible

every square centimeter not more

than

|

5

|

|||

|

On the bottle mouth

|

Not allowed

|

|||

|

Crack

|

Refractive

|

Not allowed

|

||

|

Slight crack on the sealing

surface(demanded by vacuum

leakproofness)

|

Not allowed

|

|||

|

Slight crack on the sealing

surface( not demanded by vacuum

leakproofness)

|

Allowed

|

|||

|

Bubble

|

Diameter more than 5mm

|

Not allowed

|

||

|

Diameter between 2mm and 5mm, not

more than

|

2

|

|||

|

Diameter between 1mm and 2mm, not

more than

|

3

|

|||

|

Diameter between 0.3mm and 1mm,

visible every square centimeter,

not more than

|

5

|

|||

|

Diameter below 0.3mm

|

Unlimited

|

|||

|

Cracked bubbles、surface thin

bubbles

|

Not allowed

|

|||

|

Bubbles on sealing surface

|

Not allowed

|

|||

|

Item Name

|

Index

|

|

|

Body Surface

|

Spikes on joint seam

|

Not allowed

|

|

Joint seam sticks out (mm), not

more than

|

0.5

|

|

|

Blank mold seam, finished mold

seam (mm),not more than

|

0.3

|

|

|

Baffle mark, deep-set

|

Not allowed

|

|

|

Seriously apparent wrinkles,

stripes, cold mould marks

|

Not allowed

|

|

|

The baffle mark clearly exceed

the body part above the mold joint

seam

|

Not allowed

|

|

|

Exterior wall roughened by black

dots, oil spots and dirty

mould

|

Not allowed

|

|

|

Imperfections that seriously

damage the appearance

|

Not allowed

|

|

|

That the mark is obviously

unclear

|

Not allowed

|

|

|

Inner Wall Defects

|

Sticky materials and spun glass

on inner wall

|

Not allowed

|

|

Inner wall of bottle neck

obviously convexes

|

Not allowed

|

|

|

Deformation

|

Various obvious deformations,

fat, convex or concave body,

convex bottom, bottle head

dislocated or tilted, bottom

sinks, etc.

|

Not allowed

|

4.4 The physical and chemical properties should meet requirements in table 4.

|

Item Name

|

Index

|

|

|

Internal Pressure

Resistance,MPa

|

Inflation bottle no less

than

|

1.2

|

|

Non-inflation bottle no less

than

|

0.5

|

|

|

Thermal Shock Resistance(rapid

temperature change when heated or

coldened),℃

|

Sterilization under normal

temperature

|

≧35

|

|

Sterilization under high

temperature

|

≧42

|

|

|

Internal Stress, Level

|

Actual stress≦4

|

|

|

Water Erosion Resistance

Performance, Level

|

≦HC3

|

|

|

Category

|

Inspection Item

|

Acceptable Quality

Level(AQL)

|

|

Specification

|

Capacity, height, thickness

ratio, vertical axis deviation,

bottle mouth OD, mouth ID

|

2.5

|

|

Thickness, bottle neck

|

4.0

|

|

|

Appearance Quality

|

Unevenness of mouth surface,

parallelism of mouth and bottom

surface, body Ovality, mouth

defects, cracks, inner wall

defects, deformations

|

2.5

|

|

Stoned, bubble, body

surface

|

6.5

|

|

Category

|

Item

|

Rejection Quality Level

(RQL)

|

Array

[Ac Rc]

|

|

Specification

|

Capacity, height, thickness

ratio, vertical axis deviation,

bottle mouth OD, mouth ID

|

40

|

[1, 2]

|

|

Thickness, bottle neck

|

50

|

[1, 2]

|

|

|

Appearance Quality

|

Unevenness of mouth surface,

parallelism of mouth and bottom

surface, body Ovality, mouth

defects, cracks, inner wall

defects, deformations

|

40

|

[1, 2]

|

|

Stoned, bubble, body

surface

|

65

|

[2, 3]

|

|

|

Physical and Chemical

Performance

|

40

|

[1, 2]

|

|

Kept away from rain, dust, insects and pollution. Make sure they’re leak-proof.

Design

The target of UPC mainly provides the personality service for every clients. In order to meet the demands of our clients ,We scheme the relevant management service with different vendor ,retailer.

We welcome OEM, Our R&D dept have a strong capability for developing new items in accordance with clients' requirements, Sketch designing, Engraving embossment or logo can be workable.